Solutions for Milk Collection with metering, sampling & data handling

Track the milk all the way from collection at the farm to delivery at the dairy with an solution from POUL TARP A/S

The Danish Engineering Company POUL TARP A/S was established in 1954 and has been designing, developing, and producing software and hardware solutions for the dairy industry from the beginning. We supply complete IT systems that handle all data communication between dairies, farmers, and milk trucks.

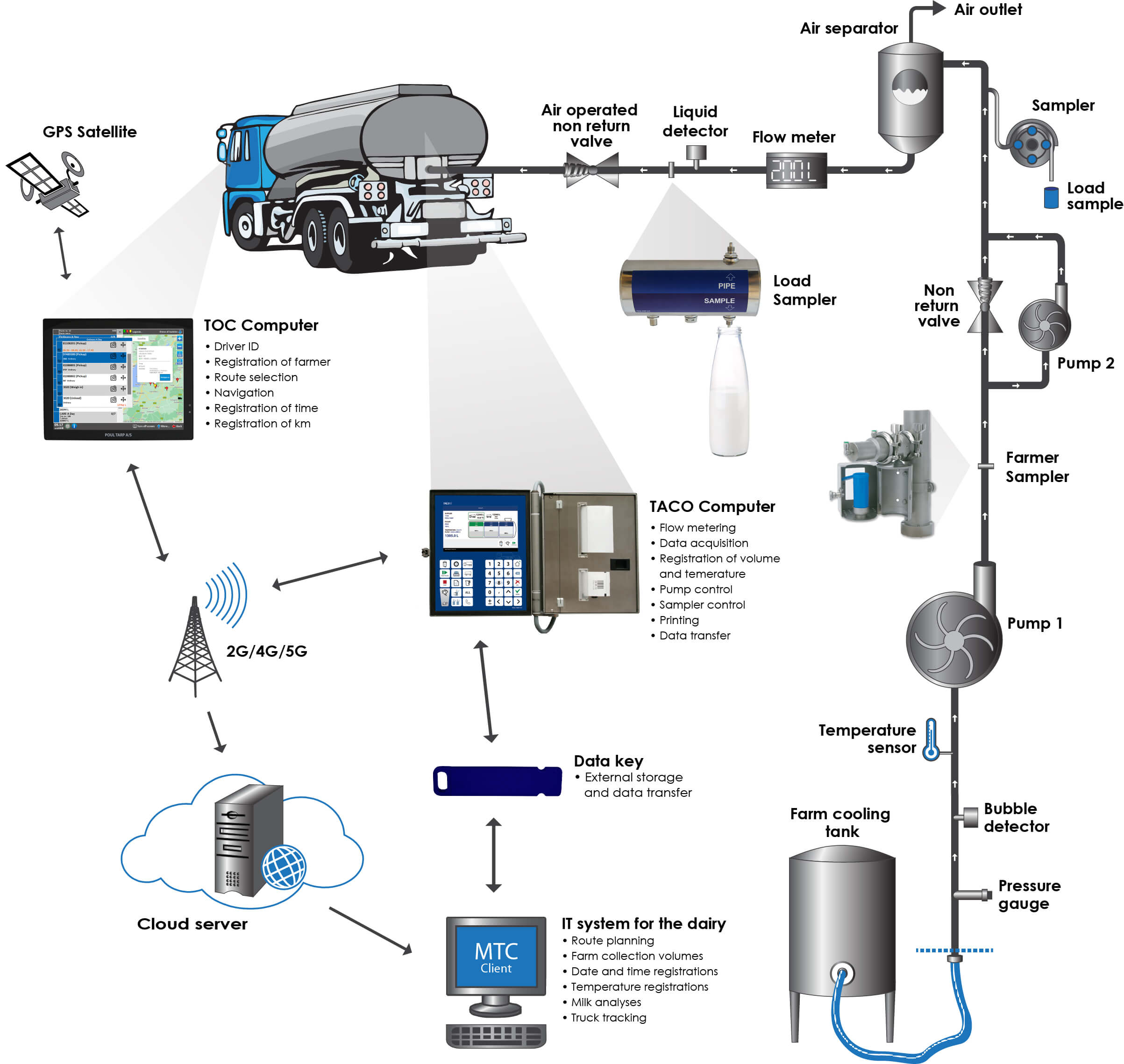

Our pump and metering solution consists of our TOC computer which is installed in the milk tanker’s cabin and informs the driver about today’s route, online messages from/to the office and navigates to the next collection point or delivery. The TACO Computer is mounted in the pump cabin where it controls the metering of the milk, the pump system, the flow meter, the milk sampler and registers the supplier and the amount of collected milk. All data is automatic sent to our IT office administration program, called TARP OFFICE. The TARP OFFICE system handles everything from monitoring the collections and deliveries to farm sample analysis, CIP data, farmer settlements, route planning, etc.

We also offers a Milk APP which is a tool for the driver that makes it easy and quick to communicate with the transport manager/office, send/receive messages, deliveries and route changes etc.

With a complete solution from POUL TARP A/S you will not only optimize your milk collection, but you will also save a considerable amount of time and money in the same process.

Below you can see more about our milk collection solutions:

The Pump- & Metering System

The high capacity pump & metering system from POUL TARP A/S is designed with a two-pump unit system with two samplers.

The pump system consists of:

- A S12/TACO computer with two printers. The computer is online with the dairy’s MCT IT-system

- The pump unit has a pumping capacity from 800 l/min. to 1500 l/min.

- The S12/TACO computer controls and regulates the pump preventing the milk to get damaged during pumping and ensures that the milk keeps its quality

- Data is transferred via GPRS to the dairy’s MTC IT-system

- Flow meter

- Air separator

- Liquid detector

- Proportional controlled pumps

- Load sampler and farm sampler

How the our pump- and meterings system flows:

With a TOC computer from POUL TARP A/S in the drivers cabin of the truck it is possible to receive route & collection information from the dairy.

Below shown is a schematic display of a complete pump-system installed in a milk tanker.

The pump-system is equipped with both a sampler for individual farm sampling in order to determine the milk quality from the individual supplier and a Load sampler for full-load sampling to document the quality of the collected milk (Load) present in the milk tanker at any given time:

IT Solutions for Milk Collection

Track the milk all the way from collection at the farm to delivery at the dairy with an IT solution from POUL TARP A/S

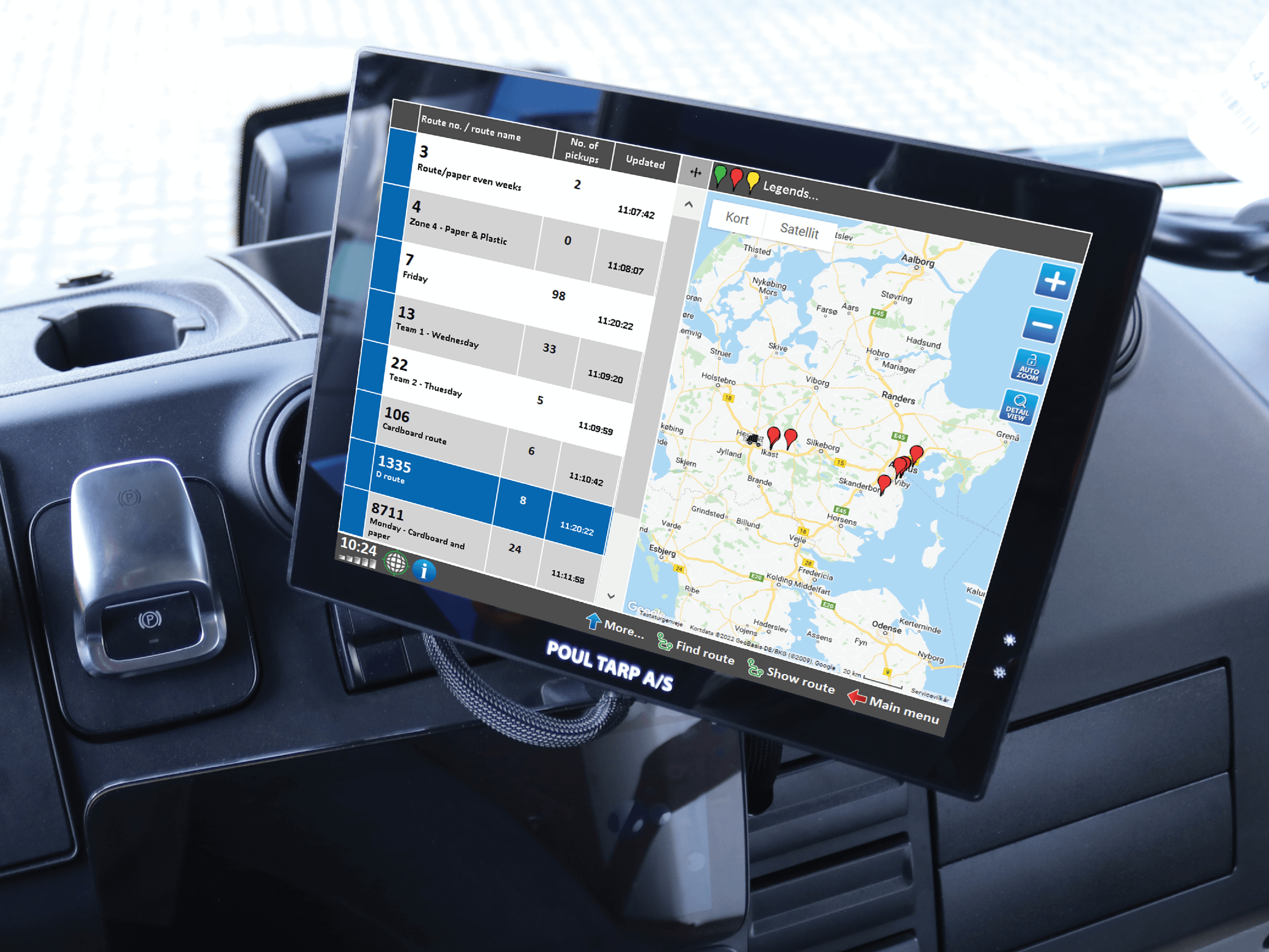

Our TOC Computer which is mounted in the cabin of our milk tankers, informs the drivers, which route to take and also the location of the milk collection points.

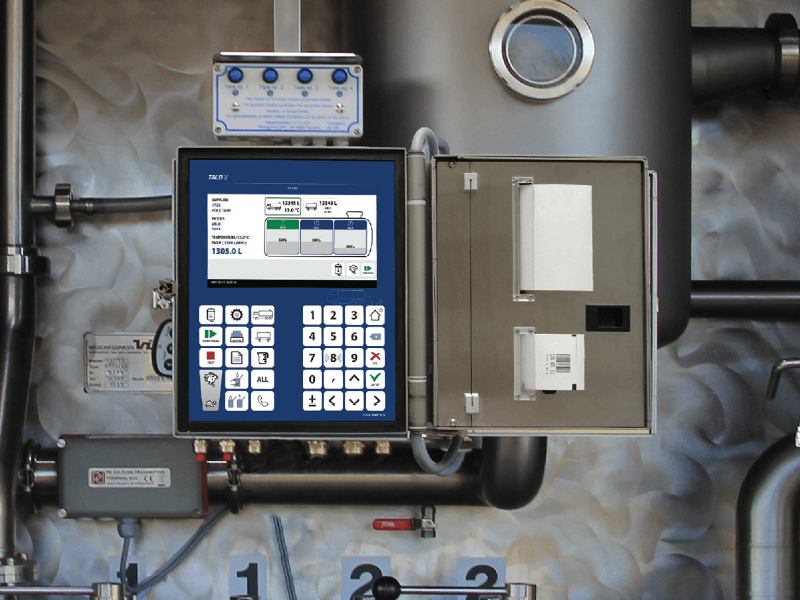

While the milk is being pumped into the milk tanker, the TACO Computer / S12 Computer takes 1-2 samples for testing in the laboratory. The TACO Computer / S12 Computer registers data such as the collection point, the quantity and the temperature.

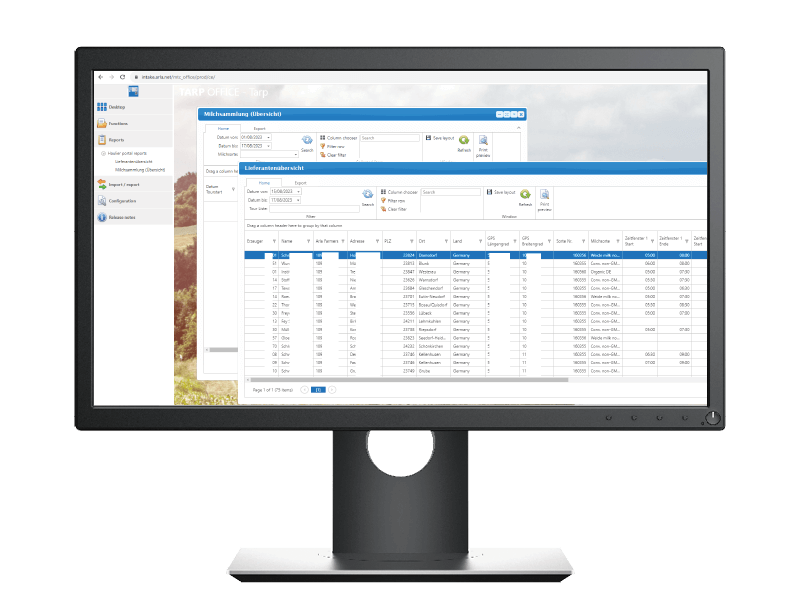

Data collected from the TOC Computer and the S12 computer is automatically sent to the MTC system, which is administered by the dairy. The route for milk collection, which is available on the TOC Computer is in fact planned by the dairy using the MTC system. The MTC system will also handle the settlement to the farmers and data on the milk quality results. The Milk APP makes it possible for, the driver, the farmer and the dairy to track the milk tanker and the milk quantity from the moment the milk is collected and until it is delivered.

TACO Pump Computer

The TACO Computer from POUL TARP A/S gives the dairy traceability in the milk collection, traceability in the milk quality and an accurate measument of the collected milk.

S12 Pump Computer

The S12 pump computer from POUL TARP A/S gives the dairy traceability in the milk collection, traceability in the milk quality and an accurate measument of the collected milk.

TOC Cabin Computer

TOC Cabin computer from POUL TARP A/S supplies the driver with an on-screen a list of today’s route and helps the driver navigate to the next pick up place/farmer. The dairy can send and receive data from the TOC cabin computer, make route changes etc.

TARP Office WebMTC

The IT solution for the office - TARP Office WebMTC is an IT system which is used at the dairy to register and collect data that are communicated between the milk tanker and the dairy.

Milk Sampling in Metering- & Pump Systems

Check the milk quality in every load with milk sampling from POUL TARP A/S.

An important part of todays milk collection is to know the quality of the milk. The milk quality can indicate how much fat the milk contains and therefor give the supplier a higher prices for milk. It also indicates whether the milk is best for food production or to be caned.

How milk sampling in tankers works

While pumping the milk into the tanker, the TACO Computer takes 1 or 2 samples of the milk. The samples are taken continuously throughout the pumping of the milk, as the milk quality is different at the bottom and at top of the tank. The samples are sent to the laboratory, where the fat and protein content in the milk is analyzed. All data from the samples will be sent to the MTC program, where the dairy can get an overview of the milk quality from the various suppliers.

Solutions for milk sampling in tankers:

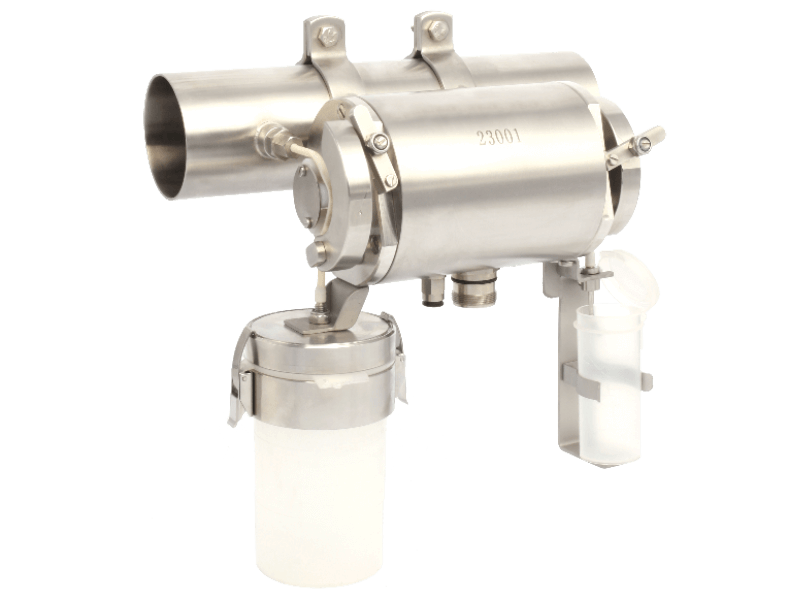

PS4 Sampler

The PS4 sampler is specially designed for installation in tankers for milk collection. PS4 is a peristaltic sampler which can take samples directly from the pipeline.

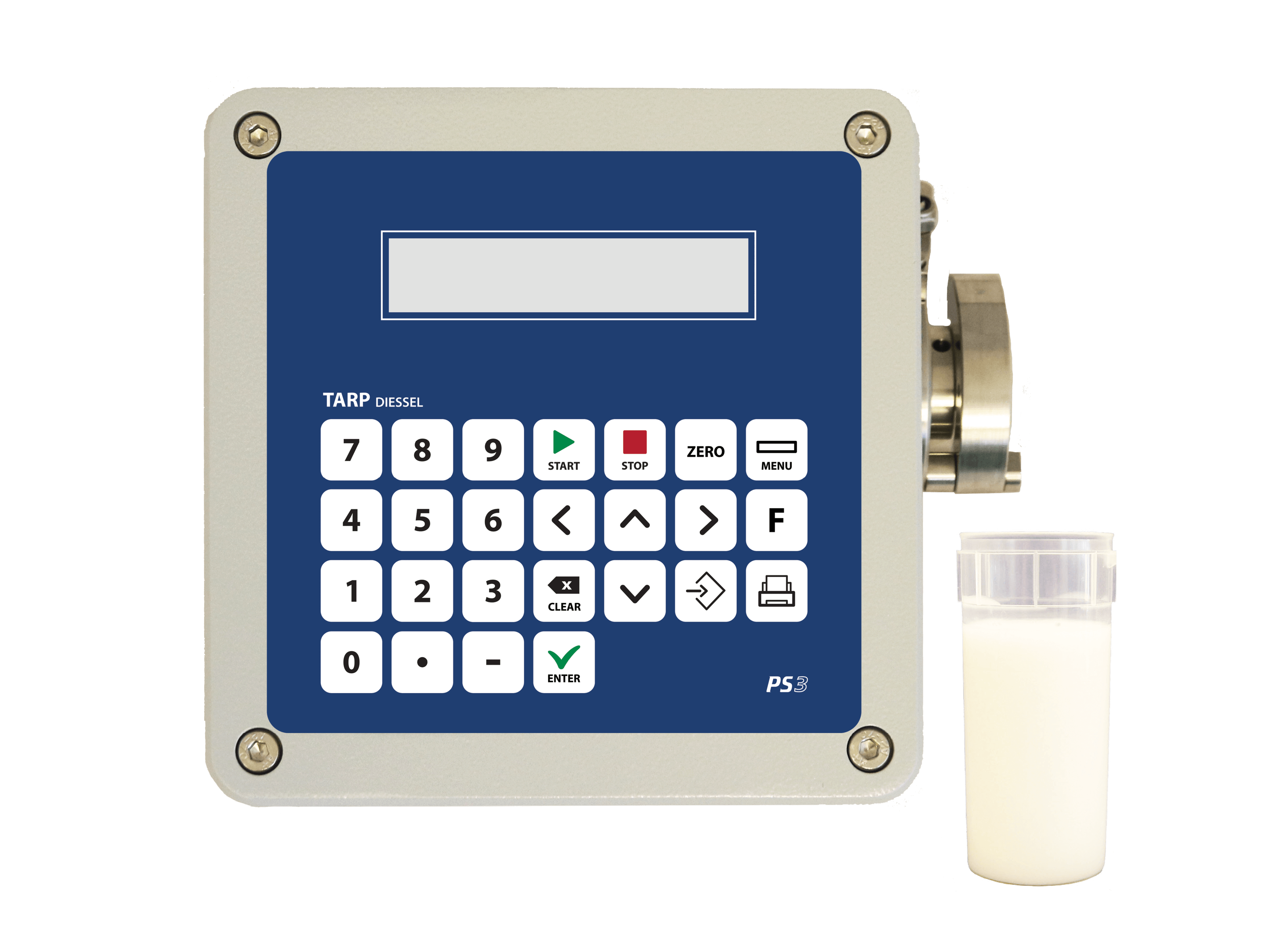

PS3 Sampler

The Sampler PS3-I is designed to be installed on milk collecting trucks. It works according to the principle of a hose pump and enables you to take the sample directly from the hose pipe.

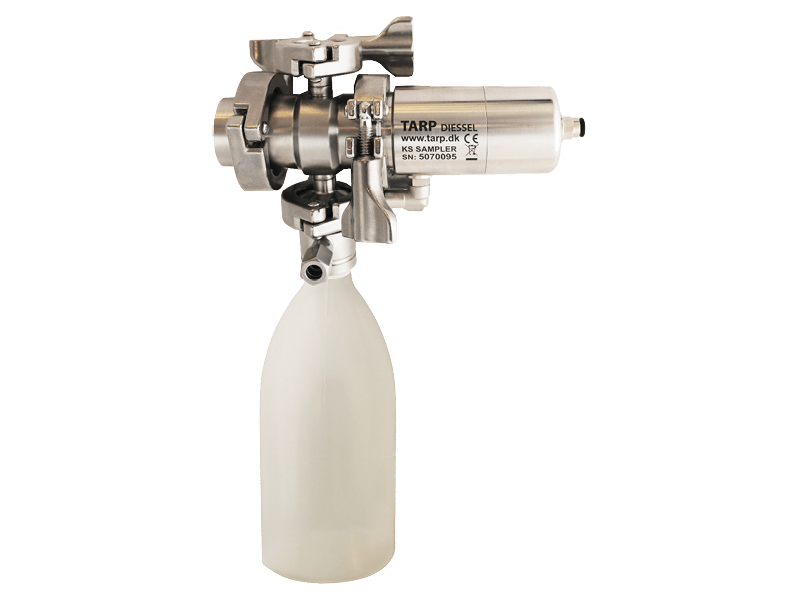

KS Sampler

The Piston KSP sampler makes it possible to sample continuously and aliquot from liquids flowing through pipelines.

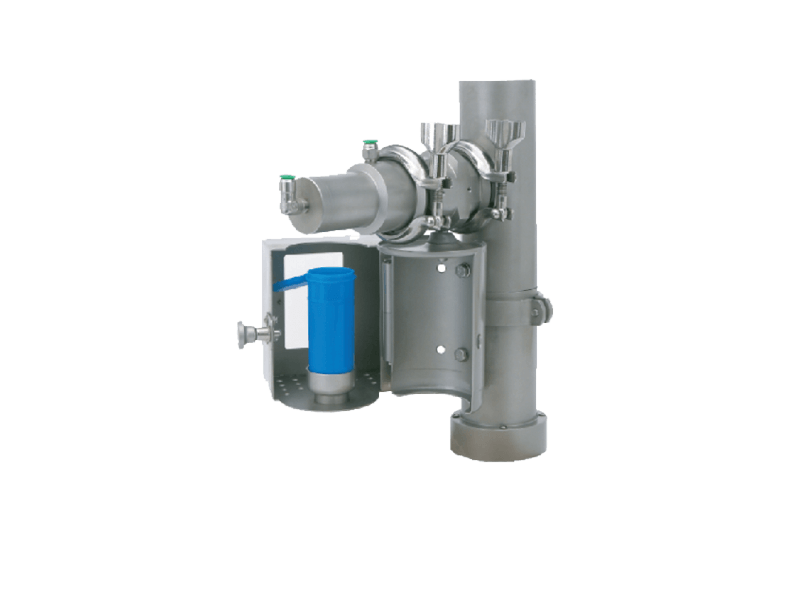

SMV4 Sampler

The SMV4 sampler is built into the pump system and is developed to take constant samples during the hole milk load that runs through the pump system.

All our hardware- and software systems meet the highest European standards. They are also MID approved and USDA design approved and inspected. We are capable of offering solutions that will meet any market requirements.

POUL TARP A/S is ISO 9001:2015 & ISO 14001:2015 certified and supports the UN Global Compact and the 10 Principles.

Contact us and get more info about our milk collection solutions, samplers and metering systems: