Milk APP Driver

App for Milk Collection

The Driver App from POUL TARP A/S is for milk tankers and semitrailers without metering systems where the driver has to register the reloaded and unloaded amount of milk. The registered data are automatically send to the MTC IT system at the office.

The Driver Milk App can be used in the following situations:

Reload milk to a tanker/semitrailer without a metering system installed

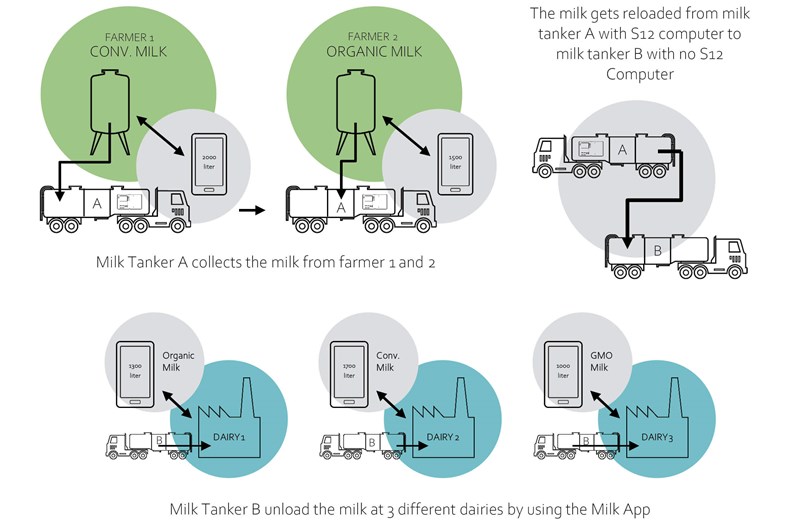

One of the functions in the Driver App is to register when a collection tanker (with S12 pump computer and metering system) reloads the milk in a tanker/semitrailer without a metering system and S12 pump computer. The Driver App will automatically register the GPS position, where milk has been reloaded. Truck and semi-trailer number, the destination dairy, volume, milk type and driver are entered in the Driver App.

The Driver App gives the transport manager and on-duty transport personnel in general an on-line tool and opportunity to see and monitor the location of the individual trucks, what has been unloaded at which dairy and when.

It is also possible to check the CIP status in the Driver App.

The illustration shows the reload of the milk:

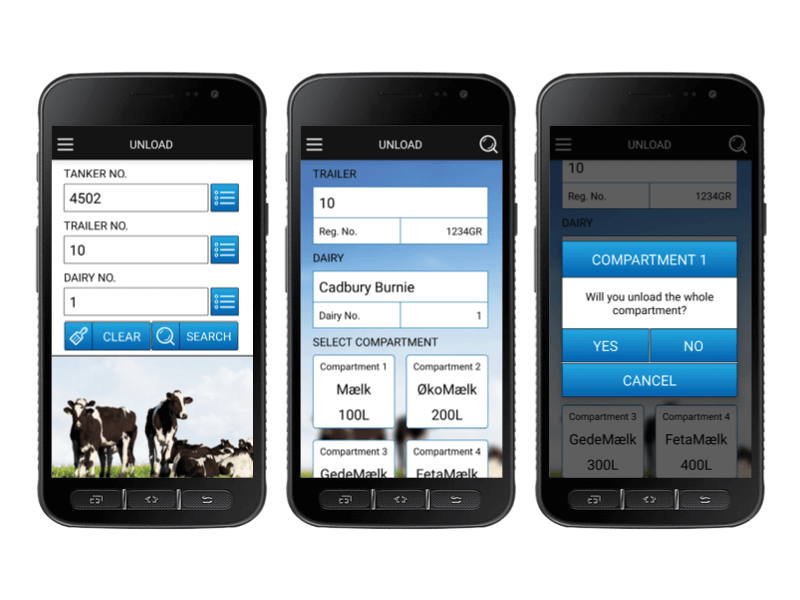

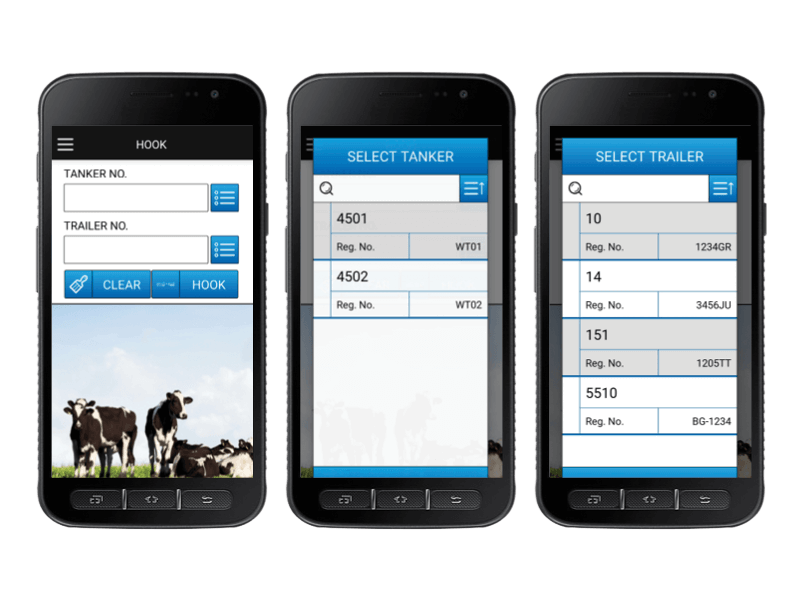

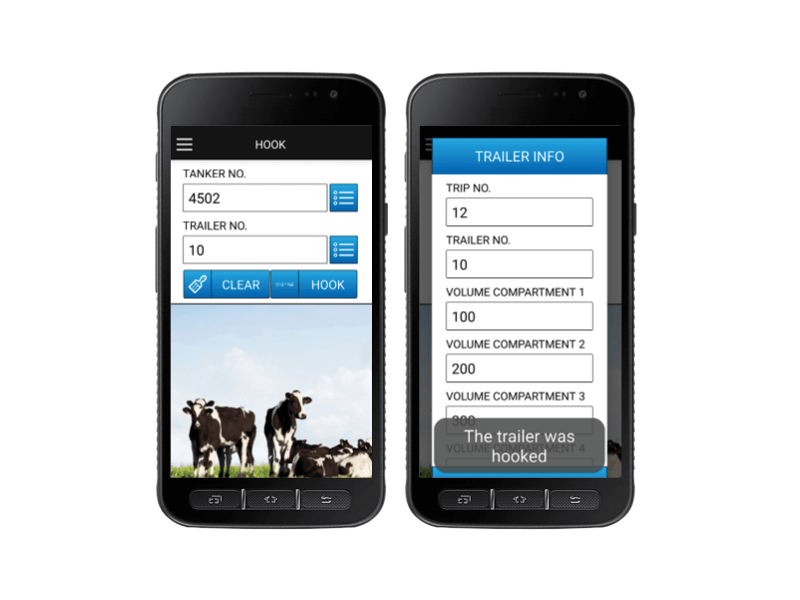

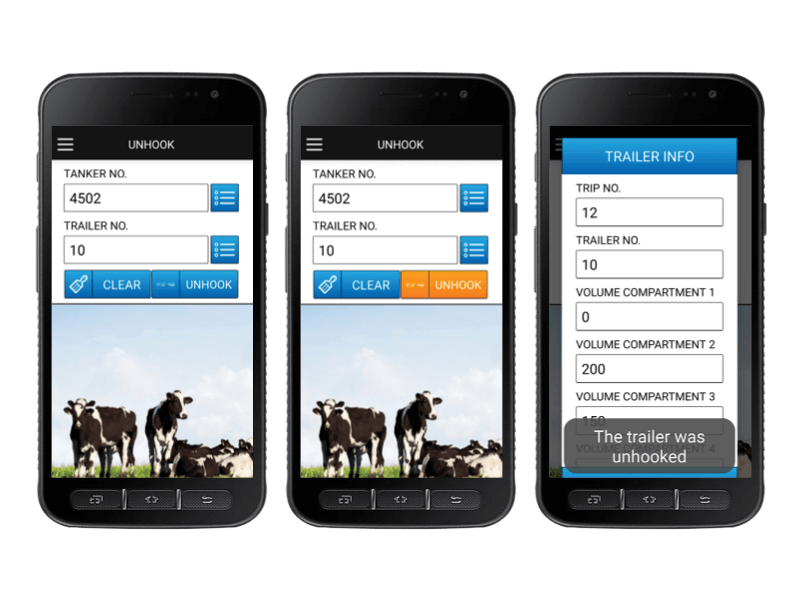

Milk-APP for trailer un-load & re-load

The Milk-APP can be used to register volume and un-loading site if a trailer arrives at the dairy with a truck with no pump/metering system installed.

Using the App you can look-up the trailer in the MTC office programme and see the volume and the driver will be routed to the correct dairy by GPS.

The driver then selects which compartment must be un-loaded – partly or full. Then the driver selects Un-load in the App and the milk is registered as un-loaded at the selected dairy in the MTC office system. Traceability is kept intact and the dairy can complete settlement to the farmer.

It is possible to use the App to register when you hook and un-hook a trailer and also for registering CIP. All registrations are send online to the MTC office programme.

Milk-APP for intermediate transport

When doing intermediate milk transport, collection and delivery to various dairies and costumers the driver can use the Milk-APP to register which product and volume are being loaded into the different truck compartments and/or trailer and where it is un-loaded. The dairies and customers are identified by GPS.

Any rules for mixing milk quality are setup and handled by the MTC office program and will be shown in the Milk-APP.

Load & unload traceability is available in the MTC office system.

CIP registration of truck and trailer is possible in the Milk-APP.

Computer Solutions

Track the milk all the way from collection at the farm to delivery at the dairy with an IT solution from POUL TARP A/S

Our TOC Computer which is mounted in the cabin of our milk tankers, informs the drivers, which route to take and also the location of the milk collection points.

While the milk is being pumped into the milk tanker, the S12 Computer takes 1-2 samples for testing in the laboratory. The S12 Computer registers data such as the collection point, the quantity and the temperature.

Data collected from the TOC Computer and the S12 computer is automatically sent to the MTC system, which is administered by the dairy. The route for milk collection, which is available on the TOC Computer is in fact planned by the dairy using the MTC system. The MTC system will also handle the settlement to the farmers and data on the milk quality results. The Milk APP makes it possible for, the driver, the farmer and the dairy to track the milk tanker and the milk quantity from the moment the milk is collected and until it is delivered.

S12 Pump Computer

S12 Computer from POUL TARP A/S gives the dairy traceability in the milk collection, traceability in the milk quality and an accurate measument of the collected milk.

TOC Cabin Computer

TOC Cabin computer from POUL TARP A/S supplies the driver with an on-screen list of today’s route and helps the driver navigate to the next pick up place/farmer.