S12 Pump Computer

S12 Pump Computer for Milk Collection

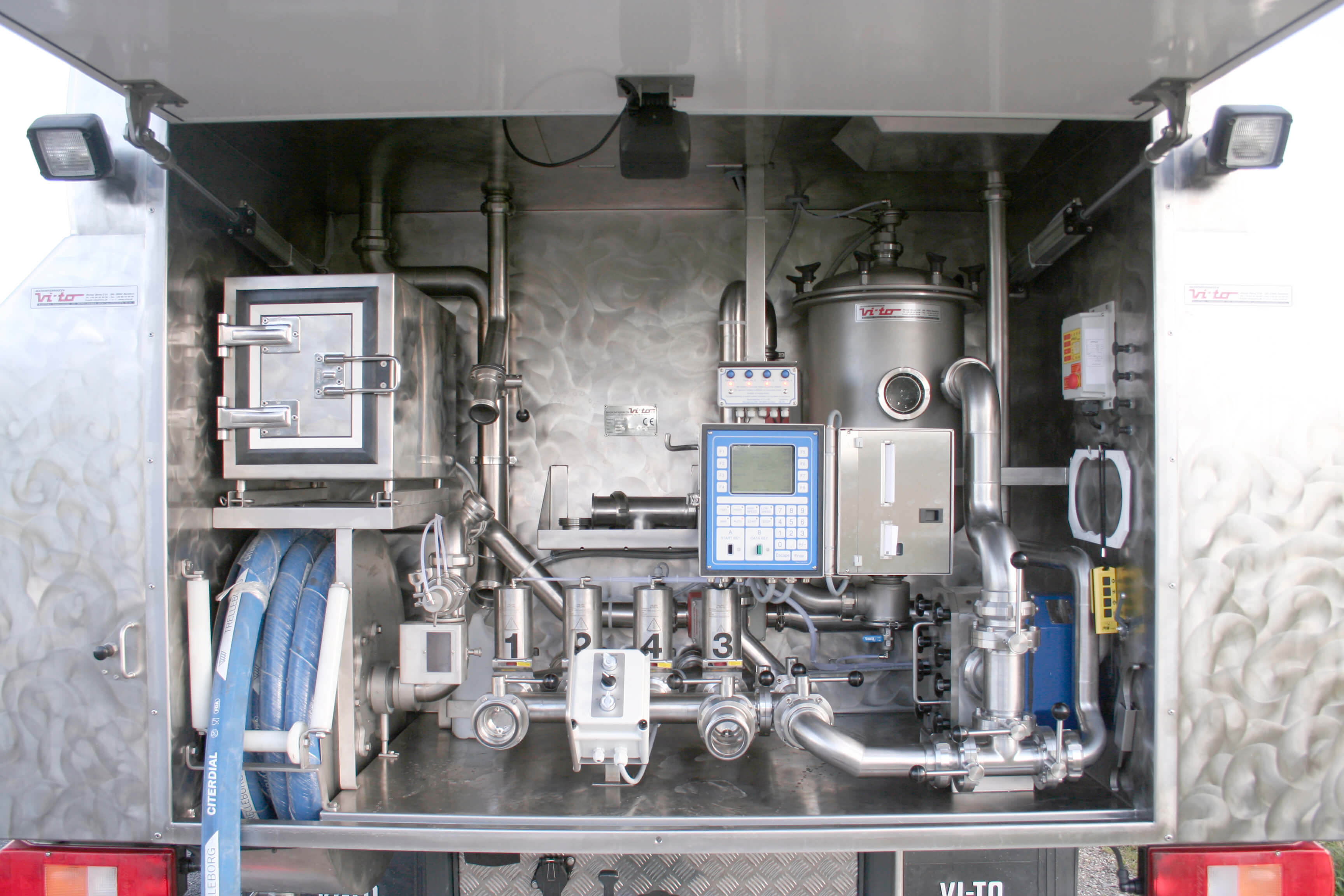

The S12 Pump Computer from POUL TARP A/S is a data-collecting pump computer for milk collection in milk tankers.

The S12 Computer is mounted in the pump system on the tanker and registers the farmer/collection point, measures the collected milk, takes samples and controlls the pump system.

With an integrated GPS-system for tracking, identification and registration of the supplier and destination (such as CIP stations) the office can follw the milk tanker and the collected milk all the way. During a milk collection the S12 Computer takes samples of the collected milk - both supplier samples and load samples.

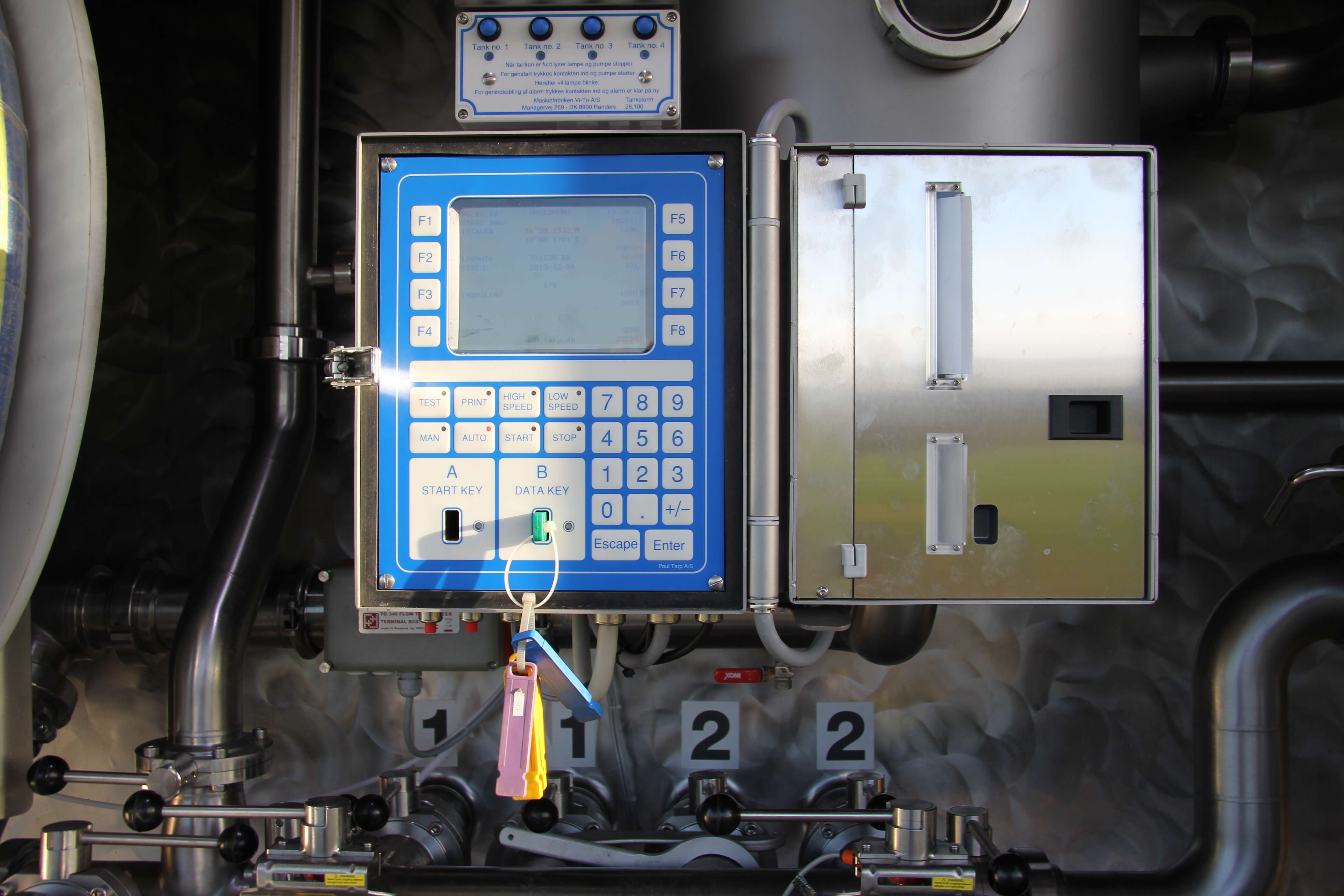

Specifikations of the S12 Computer:

- Registration of amount, temperature and pressure, control of the pump, test sampler and flowmeter

- Wireless data communication with GPRS (2G/3G/4G) between the milk tanker and the dairy

- The S12 Computer can control up to 4 test samplers for quality control during each collection

- The graphical display can be used in direct sunlight

- Big keys: 18 function keys and 12 keys with numbers

- Manual loading and unloading of data with electronic keys

- The S12 Computer has passed the OIML 177 B test

- The S12 Computer has a 112 mm receipt printer and a 55 mm label printer for bar code labels

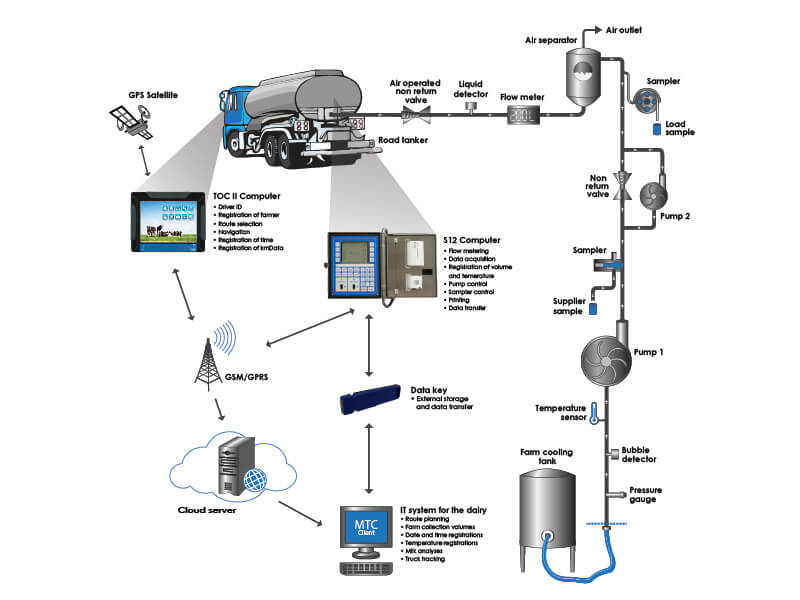

Computer Solutions

Track the milk all the way from collection at the farm to delivery at the dairy with an IT solution from POUL TARP A/S

Our TOC Computer which is mounted in the cabin of our milk tankers, informs the drivers, which route to take and also the location of the milk collection points.

While the milk is being pumped into the milk tanker, the S12 Computer takes 1-2 samples for testing in the laboratory. The S12 Computer registers data such as the collection point, the quantity and the temperature.

Data collected from the TOC Computer and the TACO II computer is automatically sent to the MTC system, which is administered by the dairy. The route for milk collection, which is available on the TOC Computer is in fact planned by the dairy using the MTC system. The MTC system will also handle the settlement to the farmers and data on the milk quality results. The Milk APP makes it possible for, the driver, the farmer and the dairy to track the milk tanker and the milk quantity from the moment the milk is collected and until it is delivered.

TOC Cabin Computer

TOC Cabin computer from POUL TARP A/S supplies the driver with an on-screen a list of today’s route and helps the driver navigate to the next pick up place/farmer. The dairy can send and receive data from the TOC cabin computer, make route changes etc.

Milk Sampling Solutions

While pumping the milk into the tanker, the TACO II Computer takes 1 or 2 samples of the milk. The samples are taken continuously throughout the pumping of the milk, as the milk quality is different at the bottom and at top of the tank. The samples are sent to the laboratory, where the fat and protein content in the milk is analyzed. All data from the samples will be sent to the MTC program, where the dairy can get an overview of the milk quality from the various suppliers.

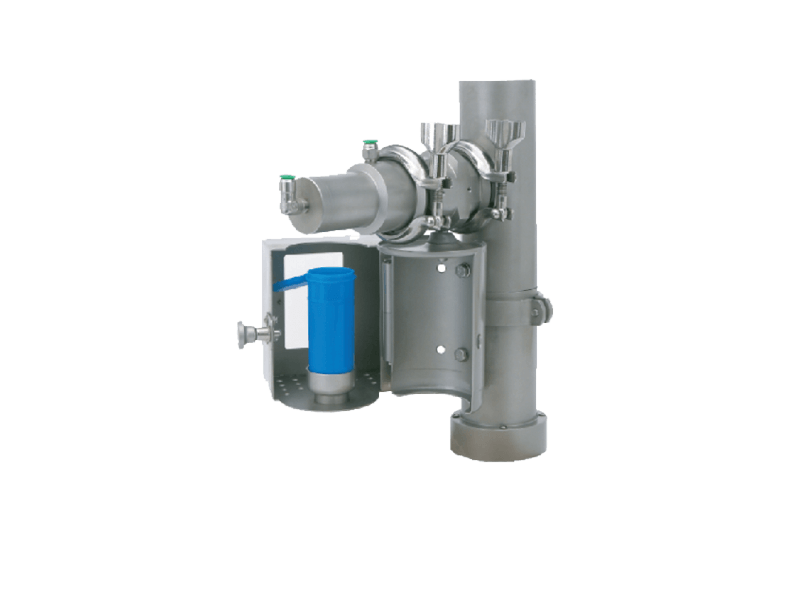

SMV 4 Sampler

The SMV 4 Sampler is developed to take samples of the milk during the pumping of the milk at the milk supplier.

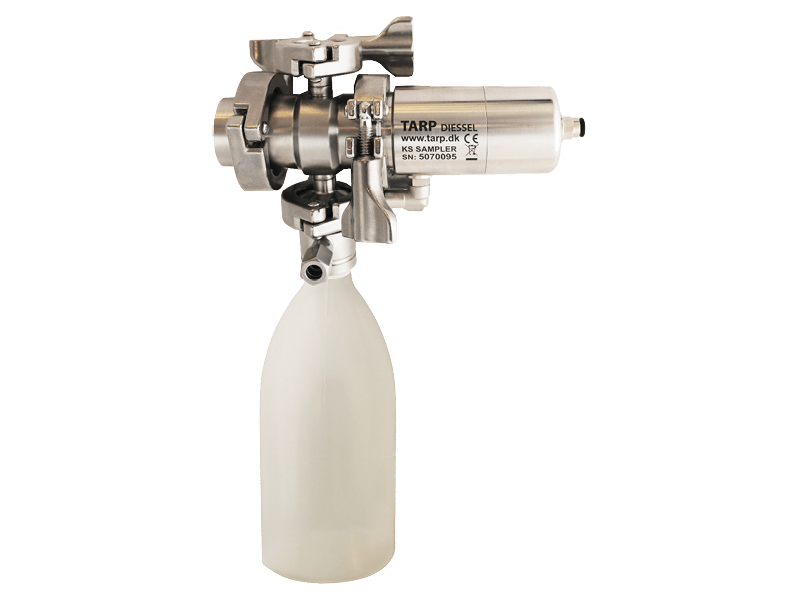

Piston KS LAC Sampler

With Piston KS LAC sampler it is possible to take samples continuously and aliquot direct from the pipeline when the milk is flowing through.